Not known Incorrect Statements About Heat Lamps / Strip Heaters - Lauro Restaurant Equipment

Strip Heater Question

Strip Heater QuestionHow Strip Heaters - Chromalox can Save You Time, Stress, and Money.

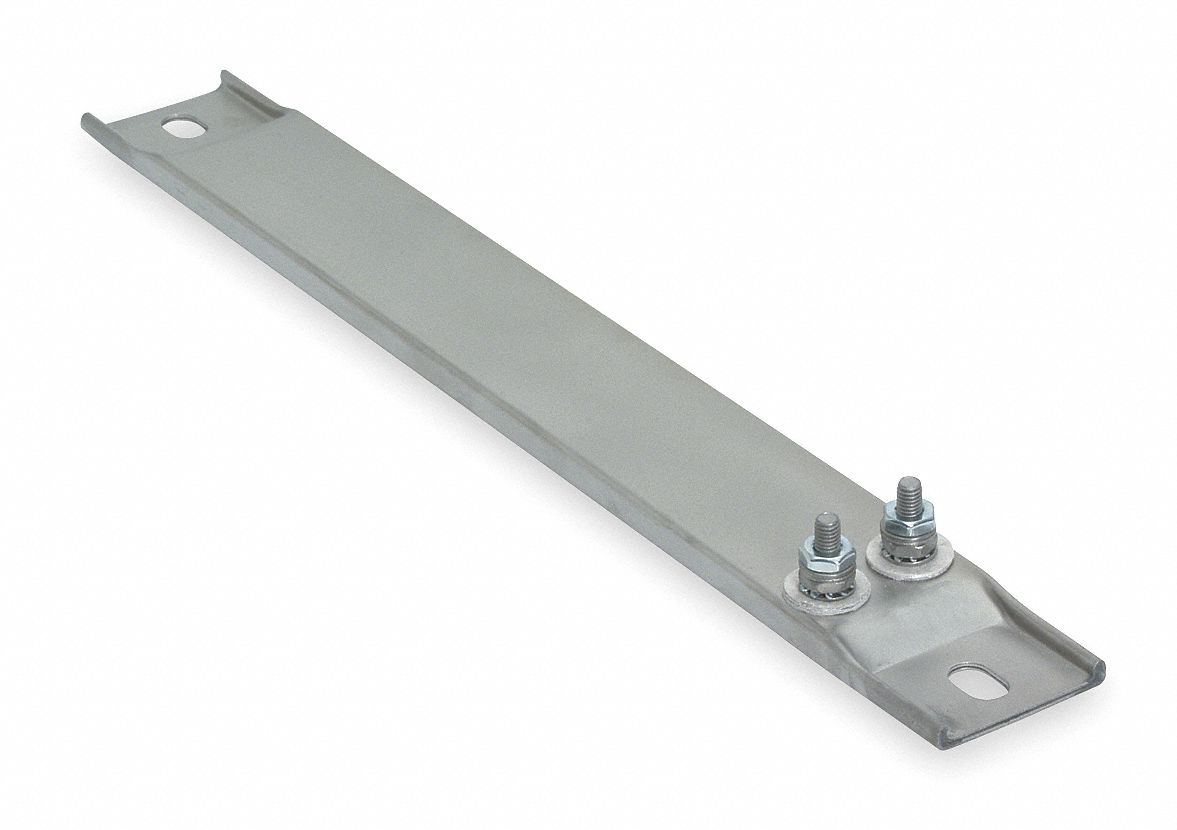

What is a Strip Heating system? Published September 4, 2018 Strip heaters are used mainly for convection-type air heating and clamp-on setups. When picking strip heaters for either, two essential aspects should be considered: The correct sheath product for withstanding any rusting and oxidizing fundamental in the procedure or environment and for withstanding the sheath temperature needed.

Stainless steel and Monel sheaths are offered at an extra charge. Maximum work and sheath temperatures are listed below. The watt density of the heating component, or watts per square inch of heated area. Go Here For the Details to be low for heating asphalt, molasses and other thick compounds with low heat transferability; it can be greater for heating air, metals and other heat conducting products.

Using a Strip Heater

Using a Strip HeaterSelection of Strip Heaters for Air Heating Figure 1 Select optimum desired operating air temperature on (D) Pick either chrome steel sheath or rust-resisting iron sheath (points E) on basis of operating conditions Draw straight line through points (D) and (E) to checking out on (F) offering maximum allowed watts per square inch Select wanted length heating system with equivalent watt density or less Selection of Strip Heaters for Clamp-On Applications Figure 2 Select optimum desired work temperature on (A) Choose either chrome steel sheath or rust-resisting iron sheath (points B) on basis of operating conditions Draw straight line through points (A) and (B) to reading on (C) giving optimum allowed watts per square inch Select preferred length heater with equivalent watt density or less Choice of Watt Density for Finned Strips Figure 3 Select a maximum preferred air temperature on A Choose sheath material to fit operating conditions Select minimum expected air velocity on B.

The Main Principles Of Strip Heater - Explosion - for Steel Drum, 30 Gallon - 240V

Watt density is given up the "How To Order" table for each strip heating system. In general, a thick material with low thermal conductivity requires a low watt density. High watt densities can be utilized with thinner liquids and with materials of high thermal conductivity. Premature loss of the element due to extreme temperature may result if the material's heat-take-away ability is low.

Heavy Duty Strip Heater for Bending Acrylic Sheets

Heavy Duty Strip Heater for Bending Acrylic Sheetsg., minutes, pressures, velocities, displacements, vibrations and others. The transducer normally includes a pressure delicate diaphragm with stress gages bonded to it. Types of Strip Heaters Heat Strips Stainless steel HCS series heat belts offer clean, reliable heat with duct temperatures as much as 649 C (1200 F) and a power density of as much as 40 W per square inch.