The 8-Second Trick For Leading The Commercial 3D Printing Revolution

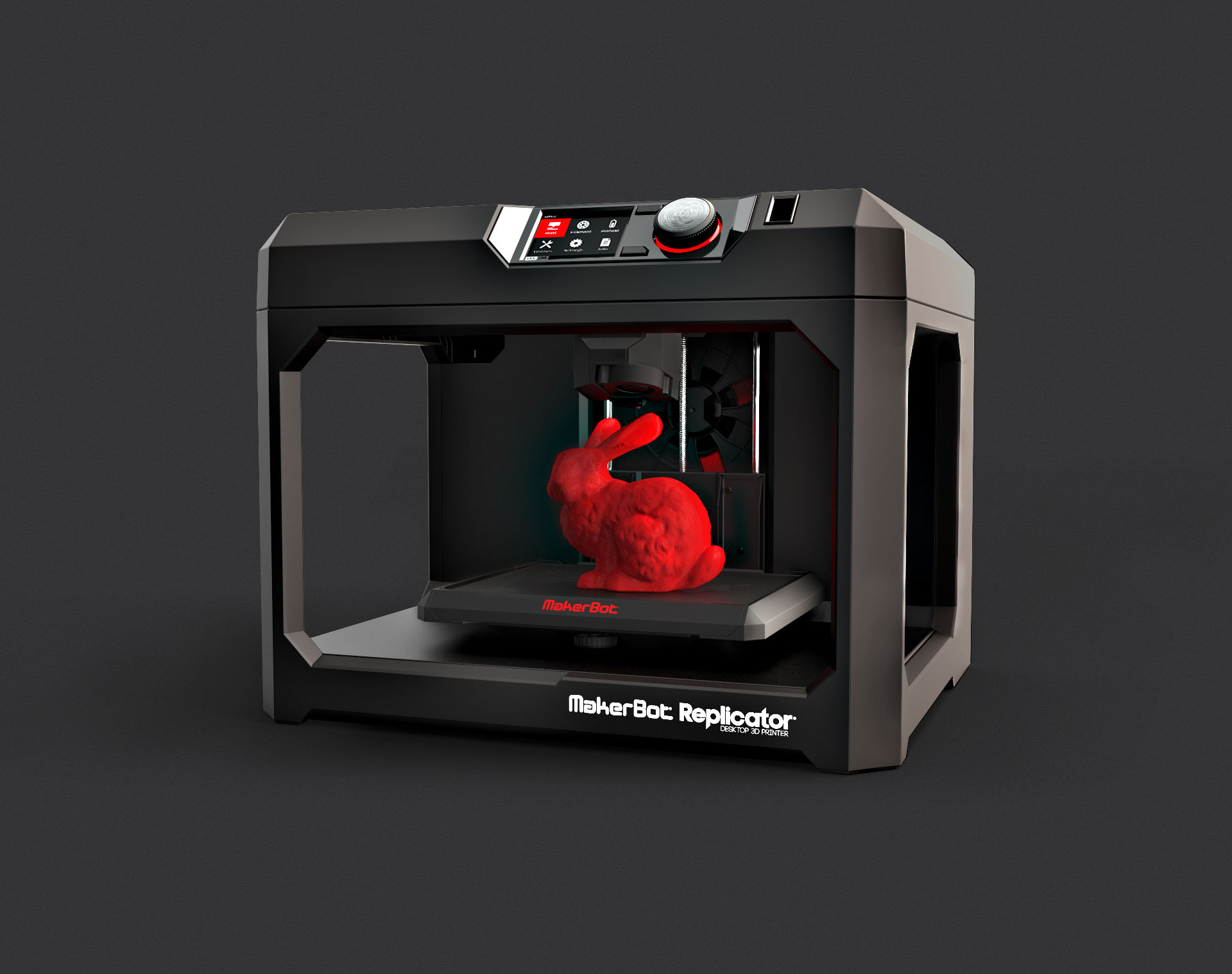

There are actually a variety of 3D printing materials, consisting of thermoplastics such as acrylonitrile butadiene styrene (Abdominals), metallics (featuring particles) , resins and porcelains . The primary producers of 3D printing materials include HP and MakerBot; a number of individual manufacturers, including 2ndMarket; and the federal government, which does not participate in 3D printing.

The earliest 3D printing manufacturing tools was built through Hideo Kodama of the Nagoya Municipal Industrial Research Institute, when he developed two additive methods for fabricating 3D versions. Kodama is credited for establishing what is currently referred to "the brand-new device discovering" through using formulas and real-world examples to produce 3D styles for analysis papers and various other sectors. Analysts have since used several procedures to integrate 3D numbers.

Creating on Ralf Baker's job in the 1920s for producing aesthetic posts ( license US423647A ), Hideo Kodama's very early job in laser cured resin swift prototyping was completed in 1981. The brand new method has been largely released throughout the building and create sector since then ( Hideo's later investigation on quick model likewise assisted mold style of a lot of industrial processes and created it achievable to develop numerous kinds of published component).

His creation was extended upon over the following three years, with the overview of stereolithography in 1984. This has led to a brand new understanding of how the different images are refined, coupled with the potential to look additional at them with the lens. Therefore significantly, many research studies have been little in scope. Some target to comprehend the design of a specific photo, while some have centered on the spatial connections of specific pictures, e.g. through matching up several various graphic series.

This Article Is More In-Depth of 3D Systems designed the first 3D color printer in 1987, which utilized the stereolithography process. A pair of years later, one more pioneer came along with the prominent 3D printing software program BICEP3D (see http://bicespectric.com). A BICEP3D color printer generated by Autodesk, the successor to the GIMP household, has nearly the exact same component. It's made along with exclusive exclusive software application coming from Autodesk.

This was complied with through progressions such as selective laser sintering and particular laser melting, among others. Such approaches provide excellent thermic management through making more than one rhythm, but are quite pricey, and do not take right into account the different functions. Additionally, we found that it is difficult to utilize many lasers as intendeds, since the aim at would be a lot as well tiny to possess a thermic result without laser sintering in itself. Therefore, we concluded that these strategies give valuable, valuable apps for tiny intendeds.

Other expensive 3D printing units were cultivated in the 1990s-2000s, although the cost of these fell significantly when the licenses run out in 2009, opening up the technology for even more consumers. The brand-new system has been extensively released, and the initial ink-jet printer has also been capable to imprint on the original 3D version it uses. The brand-new color printer is a 4-D printer, created at Boeing's Denver centers and located in Los Angeles.

There are three extensive styles of 3D printing modern technology; sintering , melting , and stereolithography . Sintering program uses effortless and cheap get access to to a wide assortment of material structures. Sintering is one of the very most wide-spread office 3D printing modern technologies since its overview in 2006. Sintering innovation can be made use of to enrich your artwork, include depth of personality to your 3D items, coating on a canvass, etc.

Sintering is a technology where the component is heated, but not to the aspect of melting, to generate high resolution things. The brand new body combines existing 3D processing devices including 3dfx Fusion, a 3dfx Fusion web server, an selection of high quality GPUs and a 4D display that provides a hassle-free, highly resizable, 3D published world. The system uses typical 3D ink-jet printers to make sure that the graphics chips are well-formulated and accurate for the preferred quality.

Steel powder is made use of for direct steel laser sintering while thermoplastic powders are made use of for particular laser device sintering. The procedure hired for heating a molten metal physical body along with a laser device produces a quick temperature level decrease in a material (Fig. 1D), as opposed to a prolonged temperature boost by a typical product (B.1). Fig. 1. Time program of thermal power loss from very hot liquified metal-rich materials in a microwave oven.

Melting techniques of 3D printing feature powder mattress combination, electron ray of light melting and direct energy deposition, these use lasers , power arcs or electron beam of lights to print objects through melting the products together at higher temperatures. The brand new approach might lead the technique to other 3D laser printer systems that would make it possible for individuals to print their very own 3D items in two means. For instance, they could use 3D color printers to print intricate 3D imprinted items with each other and could possibly use them to the world.